Steel Core Galvanized Steel Wire Rope IWRC

Advantages of steel core vs. fiber core

VS

1. The steel core wire rope of the same diameter has a larger breaking force than a fiber core wire rope, and the load it bears is also larger;

2. The steel core wire rope has better impact resistance and pressure resistance than the fiber core wire rope. The steel core wire rope is suitable for multi-layer winding;

3. Steel core wire rope is higher than fiber core wire rope in terms of high temperature resistance. Steel core wire rope is generally selected for high temperature occasions;

4. The fiber core wire rope is softer than the steel core wire rope;

5. The lubrication of fiber-core steel wire rope is better than steel-core steel wire rope for storing oil.

Specification

| Name | Steel wire rope with Steel Core |

| Diameter | 0.3-16mm,etc |

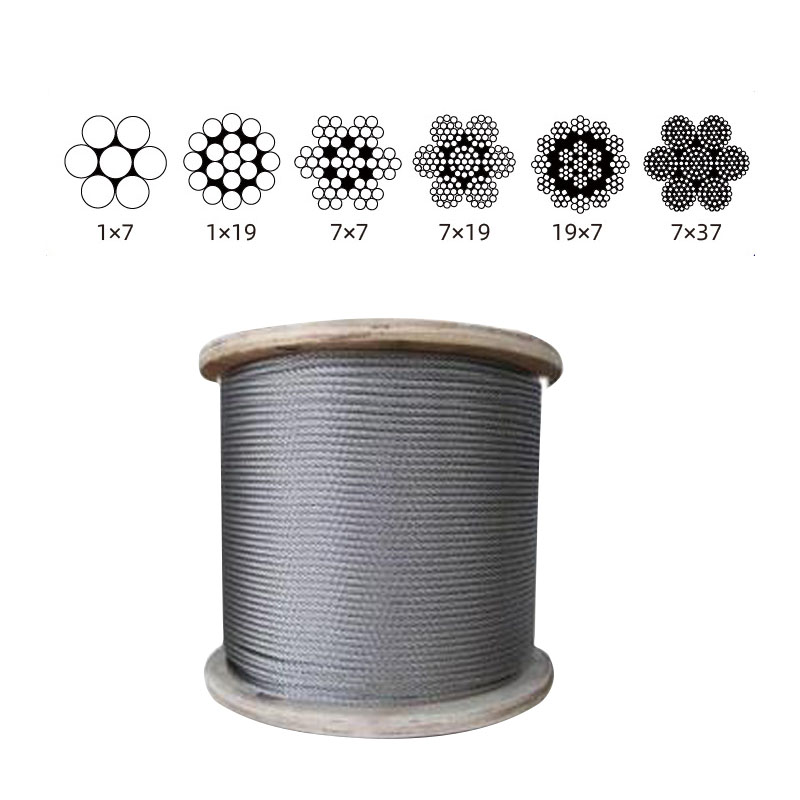

| Construction | 1*7, 1*19, 7*7, 7*19, 19*7, |

| Length | 500 mm/reel, 1000 mm/reel, 2000 mm/reel , or as your requirements |

| Material | Carbon steel, hemp core/cotton core/PP core |

| tensile strength | 1470,1570,1670,1770,1870,1960,2160MPA |

| Surface treatment | Electro-galvanizing, or hot-dip galvanizing |

The History of Wire Rope

Modern wire rope was invented by Wilhelm Albert, a German mining engineer, between 1831 and 1834. He developed them in order for work in the mines in the Harz Mountains. This rope replaced weaker natural fiber ropes, like hemp rope and manila rope, and weaker metal ropes, like chain rope.

Albert’s rope was constructed of four three-stranded wires. In 1840, a Scot named Robert Stirling Newall improved upon this model. A year later in the United States, American manufacturer John A. Roebling started producing wire rope, aimed at his vision of suspension bridges. From there, other interested Americans, such as Erskine Hazard and Josiah White, used wire rope in railroad and coal mining applications. They also applied their wire rope techniques to provide lift ropes for something called the Ashley Planes project, which allowed for better transportation and increased tourism in the area.

Approximately twenty-five years later, back in Germany in 1874, the engineering firm Adolf Bleichert & Co. was founded. They used wire rope to build bicable aerial tramways for mining the Ruhr Valley. Years later they built tramways for both the Wehrmacht and the German Imperial Army. Their wire rope systems spread all across Europe, and then migrated to the USA, concentrating at Trenton Iron Works in New Jersey.

Over the years, engineers and manufacturers have created materials of all kinds to make wire rope stronger. Such materials include stainless steel, plow steel, bright wire, galvanized steel, wire rope steel, electric wire, and more. Today, wire rope is a staple in most heavy industrial processes. Wherever heavy duty lifting is required, wire rope is there to facilitate.

Related PRODUCTS

-

E-mail

-

Phone

-

Whatsapp

whatsapp

-

Wechat

Wechat

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu